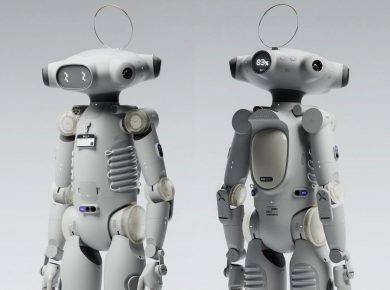

Circus Autonomy One sits behind a pane of glass almost like an exhibit. Two robotic arms glide with clinical accuracy, moving from ingredient silos to induction surfaces and finishing stations with no hesitation and no downtime. A meal appears at a collection window in under a few minutes, hot and portioned and identical to the last one. Nobody wears an apron. Nobody calls out orders. Nobody wipes down counters. This is not a kitchen. It is infrastructure.

The unit is built by Circus SE in Munich and occupies seven square meters in total. That footprint is smaller than many home bathrooms. Yet within that confined space, the system can produce up to 120 meals an hour. A dish every thirty seconds from start to finish. The feedstock flows from climate-controlled silos. The heating is tuned by an AI that not only understands timing but continuously calibrates cooking variables. Every component is tracked, rotated, replenished, and cleaned by the system itself. The internal dishwasher comes from Winterhalter, a company better known for handling the cleanup in large canteens and industrial kitchens. Here, it’s just another internal organ inside a mechanical stomach.

Circus calls it a solution to labor shortages. That is technically accurate. Only the phrasing makes it sound like a kindness. The CA-1 is a total replacement for an entire segment of restaurant labor. Prep work, cooking, expediting, dishwashing, quality control, and inventory monitoring are absorbed into the machine. This is not a “robotic assistant” working under a human chef. It is a vertically integrated, closed-loop system programmed to operate without any human technician in the loop during normal use. The intent is obvious. Remove friction. Remove mistakes. Remove cost. And yes, remove people.

One unit is currently installed in REWE supermarkets in Germany. Customers walk up, order through a screen, and receive their meal from a small collection hatch. The interaction feels casual. The outcome is anything but. Every order placed here is a meal that did not require a kitchen staff, training cycles, shift scheduling, smoke hoods, or human error. The emotional warmth associated with cooking is separated from the act entirely. The consumer receives convenience, consistency, and speed. The labor that once stood behind that process is nowhere to be seen.

This is a ghost kitchen made physical and mobile. A restaurant reduced to logic gates and food-safe steel. The unit can be placed in a supermarket foyer or a university hallway. A hospital cafeteria could run one around the clock. Fast-food executives and food service contractors are watching because the numbers make undeniable business sense. A box that never calls in sick. A kitchen that cleans itself. A cook that never burns a dish. A cost center that never negotiates. Scaling becomes a matter of transport and hookup.

The moral weight does not vanish just because the design is clever. Every technological leap requires tradeoffs, and this one is no exception. A system like the CA-1 does not slide into the market softly. It enters with the explicit purpose of restructuring where labor fits into the food economy. The narrative of labor shortages often hides a more difficult conversation. The shortage exists because the compensation for these roles has historically been low, hours have been long, stress is high, and turnover is constant. Instead of improving wages, working conditions, and staffing support, the industry now has access to a machine that sidesteps the problem entirely.

This path creates a restaurant model where human presence becomes a luxury. High-end dining may still rely on theater, craft, and personality. Mid-tier and mass-scale food service will increasingly look like CA-1: clean, fast, controlled, anonymous. The question is not whether this system will be adopted. It already has been. The question is how quickly it proliferates and whether society has the time or willingness to address what falls away in the process.

Circus SE even points to defense sector applications. A self-contained food production unit that can operate in remote bases, disaster zones, or mobile deployments is a compelling pitch for militaries. Once inserted into that pipeline, the unit achieves a level of durability and logistical proof that accelerates civilian adoption. Institutional kitchens, corporate dining halls, airports, stadiums, offshore facilities, boarding schools, senior-living complexes. Any place that prioritizes volume and consistency.

Automation rarely arrives gently. It appears in polished form, already deployed, already functioning, and the implications trail behind. The CA-1 is not a concept waiting for regulatory clearance or a prototype searching for funding. It is here. It works. It feeds people. And it silently reshapes the definition of work in kitchens across the world.